CHICAGO PNEUMATIC SCREW AIR COMPRESSOR

The Chicago Pneumatic Screw Compressor is the only air compressor that can meet all the needs of the job, the job is superior in performance and durability. Therefore, it is used in many areas of life and laboratories. Some questions are raised such as:

☞ What are the advantages of Chicago Pneumatic Screw Compressors?

☞ What are the characteristics and durability of the Chicago Pneumatic Screw Air Compressor?

☞ What are the specifications of the Screw Air Compressor?

All these questions will be answered by us through the article below.

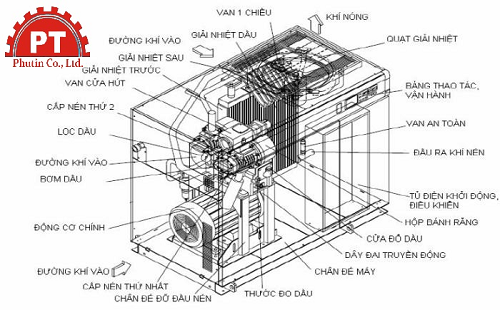

Structure of Chicago Pneumatic screw air compressor

● Electric motor and coupling: Most screw compressors use 3-phase motors. This part is responsible for converting electrical energy into mechanical energy.

● Valve: Responsible for regulating the flow of compressed air inlet to the machine.

● One-way valve: Installed at the outlet of compressed air, which is responsible for allowing the gas to only go in a certain direction.

● Oil stop valve: Located at the bottom of the compressor head assembly, it is responsible for preventing oil from spilling from the compressor head to the motor when the machine is not in operation.

● Minimum pressure valve: This type of valve helps to maintain a minimum pressure at the oil tank. They also function similarly to check valves.

● Thermostat valve: Responsible for regulating the amount of lubricant going up on the cooler.

● Solenoid valve: Responsible for opening and closing the suction neck.

● Safety valve: Ensure the machine is always safe from short-circuit and fire.

● Oil tank and oil separator: The tank is responsible for storing engine oil. Separation filter will remove machine oil from compressed air, ensuring air quality.

● Oil return pipeline: It is responsible for collecting oil at the bottom with a filter to separate the oil left after the filtration process.

● Oil filter: This type of filter helps to filter the dirt in the oil, installed between the oil tank and the screw.

● Primary filter: Helps limit the impact from sand, gravel, dirt, ... on the machine.

● Cooler: Cools the compressed air before it is taken out of the container.

● Oil cooler: This unit is located next to the cooler with the ability to cool oil and compressed air.

● Cooling fan: Gives the ability to blow air around the oil and compressed air coolers.

● Pressure sensor: Controls the pump to operate within the rated pressure range.

● Temperature sensor: It is responsible for measuring the temperature of the machine and giving warnings if the machine temperature is too high.

● Overload sensor: Or it is the relay, which helps protect the machine from short-circuits, fires, and misoperation.

● Various other parts such as switch, LCD control screen, protective cover, etc

The principle of operation of the Chicago Pnuematic screw air compressor

➠ Working mechanism: Using positive rotation mechanism, twisting from bottom to top, from outside to inside to create greater pressure. Works on the principle of continuous volume change, based on two axes as the center of gravity. Includes a large shaft and a small shaft.

➠ In the compressor head of the screw air compressor system, there will be 2 screws, 1 main shaft and 1 auxiliary shaft. These two shafts have tooth grooves with the ability to engage each other. The number of teeth between the two shafts has a difference of 1-2 teeth.

➠ When the air compressor starts, observing from the intake side we can see that the pair of gears will disengage, the middle cavities of the gears are separated from each other to create a large space. This cavity is connected to the intake so it is filled with air. The air intake process will stop when the gas chamber is fully expanded, the gas volume reaches the maximum value.

➠ When the shaft rotates at a fast speed, air will be sucked into the housing through the intake port and directly into the air cavity between the two shafts. This cavity will be narrowed thanks to the tightening gears, thereby reducing the gas volume and increasing the pressure for the gas. In order to limit the leakage of compressed air, a check valve is installed at the outlet to prevent the compressed air from going back.

Applications of screw air compressor

➽ In the industrial electronics industry: The compressed air from the screw air compressor is used to support the process of manufacturing electronic components and assembling electronic components.

➽ In the manufacturing industry, compressed air is often used to control automation equipment.

➽ In the construction industry: Provide compressed air to transport and spray concrete in conditions where concrete mixers cannot be used.

➽ Mining industry: Supplying clean compressed air containing oxygen to the tunnels, mines, etc. to the workers.

➽ Medical industry: Drying, sterilizing medical equipment, drying drugs, creating an ideal environment in biochemistry rooms supplying compressed air for equipment such as X-ray machines, etc.

Specifications of screw air compressor

- CPN screw air compressor

Noise level: 70-80 dB(A)

Tank: 200, 270 or 500 liters

Flow: 220 - 1631 liters/min

Power: 3-20 hp / 2.2-15 kW

Working pressure: 8 - 13bar

Weight: 115 - 354 kg

- CPM screw air compressor

Noise level: 61-71 dB(A)

Tanks: 0, 200, 270, 500 liters

Flow: 240 - 1860 liters/min

Power: 3-20 hp / 2.2-15 kW

Working pressure: 8 - 13bar

Weight: 99 - 360 kg

- CPA-CPB-CPBg screw air compressor

Power: 7.5-50hp/5.5-37 kW

Working pressure: 7.5 - 13bar

Weight: 251 - 905 kg

Flow: 520 - 6100 liters/min

Tanks: 0, 200, 270, 500 liters

Noise level: 66-77 dB(A)

- CPVS-CPVSd screw air compressor

Noise level: 69-77 dB(A)

Tanks: 0, 200, 270, 500 liters

Flow: 300 - 6000 liters/minute

Power: 10-50hp/7.5-37 kW

Working pressure: 5.5 - 12.5bar

Weight: 280 - 925 kg

Advantages of Chicago Pneumatic Screw Compressor

✔ No intake valve, push valve

✔ Even and high flow.

✔ Small, compact, durable design (two rotating screws do not contact the body).

✔The outer shell is made of metal with solid durability, water resistance, and dust resistance, contributing to protecting the details inside the device.

✔ Smooth operation, low vibration, low noise.

✔ Less maintenance, low operating costs

If you want to get any further information, please don’t hesitate to contact!